Unplanned downtime poses a major threat to operational efficiency and financial stability. Recent data provides crucial insights into the scale of this issue and its associated costs.

Specifically, unplanned downtime has been shown to cause significant losses. Manufacturing companies are particularly vulnerable, with 82% experiencing at least one unplanned outage in the past three years. The financial impact can be severe—losses may reach up to $10,000 per hour.

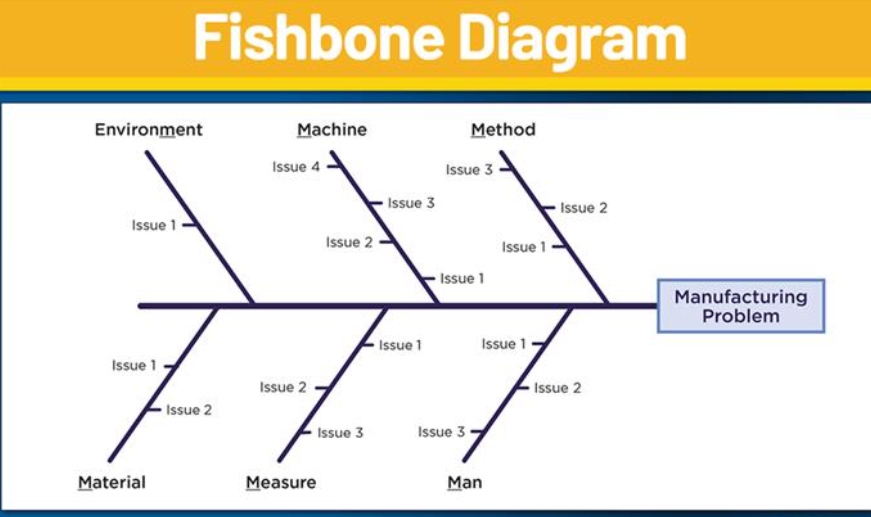

To accurately assess the total cost of downtime, it’s essential to consider MRO-related factors:

- Time spent locating parts

- Costs associated with urgent parts ordering

- Asset recovery time